Contact Us

Google HQ: Pressuremeter Testing Approach

Adjacent to Kings Cross Station and in the vibrant Coal Drops Yard, construction has been in full swing since 2018, and it is exciting to see the UK Google HQ come to life. But the design, ground preparation and ground investigations commenced long before this.

The unique, 11-storey structure, with a triple-storey basement, designed by BIG and Heatherwick Studio comprises adaptable space, and required floors spanning the full width of the building, with internal multi-storey spaces.

The design included impressive triple-storey internal spaces, a column-free western elevation and a notable roof structure with trees. Accordingly, the loads were concentrated and significant.

Challenges With Conventional Foundation Solutions

The conventional foundation solution would use piles terminating within the Thanet Sand Formation. However, this would require piles in excess of 40m long which would be timely and costly.

An alternative approach to investigation techniques and analysis was required, to ultimately limit construction risks.

Pressuremeter Testing Approach

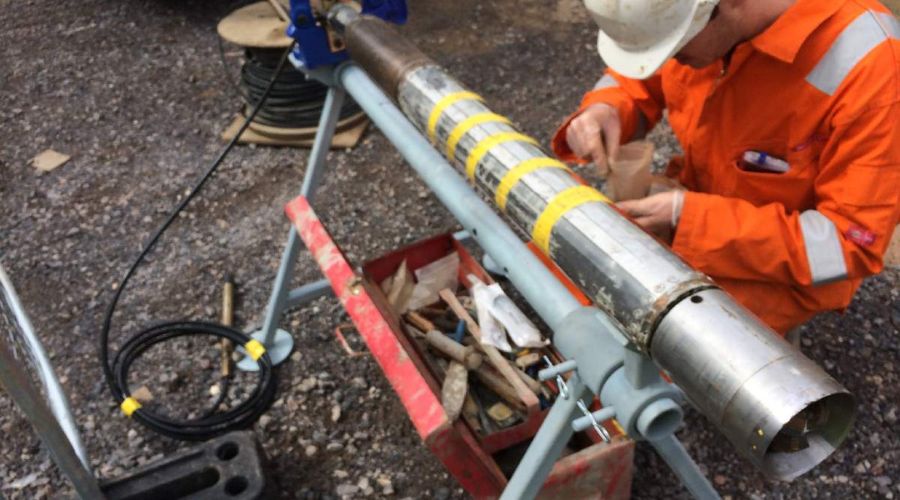

Working with structural engineers AKT II, along with the usual investigation data, the use of pressuremeter testing was advocated within the London Clay as it can provide high-quality data at small strain levels.

Despite the technique being around for decades it is used sparingly within the ground investigation industry. There is still a reliance on Standard Penetration Tests (SPTs) as they can provide multiple data points for a relatively low cost.

In contrast, the pressuremeter takes time and requires more borehole preparation, and there is a reluctance to place reliance on fewer data points for a seemingly higher cost.

Pressuremeter Testing Benefits

The results from the pressuremeter testing indicated that the London Clay was significantly stronger than when estimated through SPTs and laboratory testing.

Accordingly, the foundation design could be leaner, achieving real cost savings and a reduction in concrete with associated carbon savings.

We continue to collaborate with our supply chain to provide innovative solutions. But sometimes it is simply a case of retrieving higher-quality data.

Of course, there is a cost and time implication but the overall benefit speaks volumes. Sometimes less really is more.

How We Can Help

At Soiltechnics, we can undertake a range of site-based testing.

Contact our team at +44(0) 1604 781877 or enquiries@soiltechnics.net today to find out how we can help and learn more about the services we provide.