Contact Us

Soiltechnics Awarded New Membership with the AGS

Soiltechnics is proud to have been admitted in June 2023 as a member of the AGS (Association of Geotechnical and Geoenvironmental Specialists).

The AGS is a “not-for-profit trade association established to improve the profile and quality of geotechnical and geoenvironmental engineering”. We look forward to working with the AGS and other members to shape and implement best practices.

Membership can give Clients confidence in our commitment to the highest quality standards in the geotechnical and geoenvironmental industries.

In the construction industry, managing waste soil effectively is not just a regulatory requirement but also a significant opportunity to save costs, increase profitability, and contribute to environmental sustainability.

Effective soil management practices can offer construction companies a variety of advantages, both in terms of economics and environmental impact.

Here’s a closer look at how proper waste soil management can benefit both the environment and the economy:

Economic Benefits

Cost Savings

One of the primary advantages of effective soil management is the potential for significant cost savings. Construction projects often generate large amounts of waste soil, which can be costly to dispose of.

By reusing soil on-site or transferring surplus soil to other developments, companies can reduce the need for costly soil disposal or the purchase of new soil.

A well-crafted Materials Management Plan can help identify opportunities for soil reuse, further reducing costs.

This proactive approach helps companies optimise their resources and maximise project profitability. Additionally, reusing soil reduces the logistical costs associated with transporting new materials to the site, contributing to overall financial savings.

Avoiding Costs of Soil Disposal

Soil disposal can be expensive, especially when large volumes of waste soil accumulate. Many construction companies face steep charges for transporting and disposing of soil.

However, by managing waste soil effectively, businesses can avoid these high costs.

Reusing or redirecting soil for other purposes allows companies to save money and invest those funds in other critical areas of the project.

This also reduces the environmental impact of waste soil disposal, creating a more sustainable approach to construction.

Compliance and Avoidance of Penalties

Staying compliant with local waste management regulations is crucial for construction companies. Regulatory bodies, such as the Environment Agency (EA) and Her Majesty’s Revenue and Customs (HMRC), frequently audit construction sites to ensure proper waste disposal practices. Non-compliance can lead to hefty fines and penalties.

By adopting effective waste soil management practices, companies ensure they meet the legal requirements and avoid potential legal consequences.

Failure to comply can result in penalties, including landfill taxes. By following best practices, companies can minimise their exposure to fines and safeguard their financial interests.

Enhanced Reputation

In today’s environmentally-conscious market, companies that prioritise sustainability often enhance their reputation. Effective waste soil management demonstrates a commitment to responsible resource use and environmental stewardship.

Clients, stakeholders, and communities are increasingly choosing companies that adopt sustainable practices. This not only boosts a company’s standing but also opens up opportunities for new business.

Companies that demonstrate a proactive approach to environmental responsibility can attract more clients, gain a competitive advantage, and stand out in the marketplace.

Are you looking to improve your business’ sustainability practices and reduce costs? Contact us at Soiltechnics today to learn how we can help your company implement effective waste soil management solutions.

Environmental Benefits

Reduction in Landfill Use

Effective waste soil management helps reduce the volume of soil sent to landfills, conserving landfill space and minimising environmental impact.

Soil is a valuable resource, and diverting it from landfills ensures that it can be reused or recycled for other purposes.

This approach not only supports the conservation of land but also reduces the environmental burden caused by excessive waste.

By implementing a strategy to manage waste soil effectively, construction companies contribute to a reduction in landfill waste, thus promoting a more sustainable approach to construction practices.

Reducing the Impact of Landfills

Landfills are often seen as a necessary evil, but they pose a significant environmental threat. The more waste sent to landfills, the more pressure is put on our limited landfill space, as well as the increased environmental damage that comes from methane emissions.

By reducing the amount of waste soil sent to landfills, construction companies can minimise these environmental risks and help mitigate the overall impact on the planet.

Reduction in Greenhouse Gas Emissions

In addition to saving costs, effective waste soil management helps lower greenhouse gas emissions. The process of extracting, transporting, and processing new soil materials requires significant energy and contributes to the overall carbon footprint of a construction project.

By reusing soil or repurposing surplus material, the need for additional soil extraction and transportation is minimised.

This, in turn, reduces the amount of fuel consumed by transportation vehicles and decreases emissions of harmful gases that contribute to climate change.

By integrating sustainable soil management practices into construction projects, businesses can contribute to global efforts to reduce greenhouse gas emissions and minimise their environmental impact.

Minimising Soil Loss

Soil is a limited and increasingly valuable resource. The construction and agricultural industries both contribute to the depletion of this essential resource, which is vital for maintaining healthy ecosystems and supporting biodiversity.

By adopting sustainable soil management practices, construction companies can help preserve this resource for future generations. Shifting to a model of soil regeneration, rather than waste, can help ensure that soil is used efficiently and kept in circulation.

This transition is a key component of the circular economy, where materials are reused and waste is minimised, contributing to a more sustainable and environmentally responsible industry.

Moving Towards a Sustainable Future Through Effective Soil Management

Effective waste soil management in the construction industry presents a win-win scenario for both the environment and the economy.

By reducing landfill use, minimising the extraction of virgin soil, and cutting greenhouse gas emissions, construction companies can make meaningful contributions to environmental sustainability.

These environmental advantages, when combined with the economic benefits of cost savings, regulatory compliance, and enhanced business reputation, make effective soil management a strategic priority for any construction company.

The importance of proper soil management will only grow as regulatory pressures increase and environmental concerns continue to shape the construction industry.

By embracing these best practices, construction companies not only improve their sustainability efforts but also ensure their long-term profitability and success in a competitive marketplace.

How We Can Help

Contact us at enquiries@soiltechnics.net today to explore how our expert soil management solutions can help your business thrive while supporting environmental sustainability and driving cost-efficiency.

AJ Retrofit Live this week delivered another impressive lineup of speakers and case studies. It was especially interesting to learn more about the design ethos and progress being made at The London School of Economics, 35 Lincoln’s Inn Field.

The FabricSurvey team carried out the retrofit building project investigation in the Autumn of 2023, and seeing the progress made by the team and their ongoing commitment to the net zero transformation is inspiring.

Sustainable Retrofit: Firoz Lalji Global Hub

The redevelopment of 35 Lincoln’s Inn Field into the Firoz Lalji Global Hub, comprises a deep retrofit which has taken a twist on the typical heritage approach to preservation, along with a focus on the recycling and reuse of the building’s original fabric into the new building.

It is also the first of LSE’s buildings to reach Net Zero, Passivhaus and WELL Platinum Certification standards, despite being a retrofit building project.

Retrofit Project Investigations On Key Structural Elements

Particularly impressive to see was the proposal to reuse the masonry bricks from both the internal walls and façade to form the entrance to the Agora Space. The FabricSurvey included careful removal and retrofit testing of brick samples for their compressive strength to inform their suitability for re-use and aid the overall project sustainability goals.

FabricSurveys’ retrofit project investigations were also undertaken on the retained steel frame, floor plates, window lintels, decorative stone façade and balconies where the new teaching facilities in the two-storey vertical extensions will be located.

The progress at the Firoz Lalji Global Hub highlights the potential of sustainable retrofitting in preserving architectural heritage, while also achieving ambitious environmental standards.

I’m excited to see the completed building and am already looking forward to next year’s AJ Retrofit Live conference.

Browse our news page for updates on some of Soiltechnics’ own future projects, or get in touch with a member of our team today at enquiries@soiltechnics.net to learn more about the services we offer.

Dr Matthew Hooper

Director

Adjacent to Kings Cross Station and in the vibrant Coal Drops Yard, construction has been in full swing since 2018, and it is exciting to see the UK Google HQ come to life. But the design, ground preparation and ground investigations commenced long before this.

The unique, 11-storey structure, with a triple-storey basement, designed by BIG and Heatherwick Studio comprises adaptable space, and required floors spanning the full width of the building, with internal multi-storey spaces.

The design included impressive triple-storey internal spaces, a column-free western elevation and a notable roof structure with trees. Accordingly, the loads were concentrated and significant.

Challenges With Conventional Foundation Solutions

The conventional foundation solution would use piles terminating within the Thanet Sand Formation. However, this would require piles in excess of 40m long which would be timely and costly.

An alternative approach to investigation techniques and analysis was required, to ultimately limit construction risks.

Pressuremeter Testing Approach

Working with structural engineers AKT II, along with the usual investigation data, the use of pressuremeter testing was advocated within the London Clay as it can provide high-quality data at small strain levels.

Despite the technique being around for decades it is used sparingly within the ground investigation industry. There is still a reliance on Standard Penetration Tests (SPTs) as they can provide multiple data points for a relatively low cost.

In contrast, the pressuremeter takes time and requires more borehole preparation, and there is a reluctance to place reliance on fewer data points for a seemingly higher cost.

Pressuremeter Testing Benefits

The results from the pressuremeter testing indicated that the London Clay was significantly stronger than when estimated through SPTs and laboratory testing.

Accordingly, the foundation design could be leaner, achieving real cost savings and a reduction in concrete with associated carbon savings.

We continue to collaborate with our supply chain to provide innovative solutions. But sometimes it is simply a case of retrieving higher-quality data.

Of course, there is a cost and time implication but the overall benefit speaks volumes. Sometimes less really is more.

How We Can Help

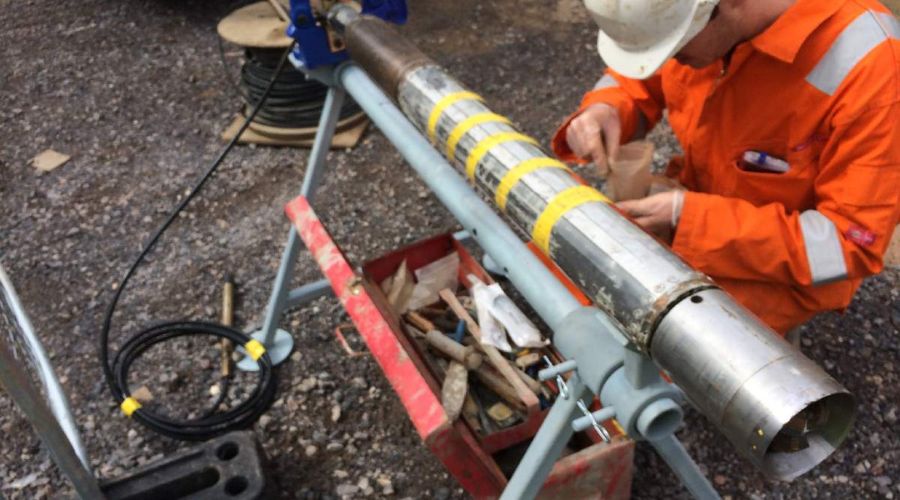

At Soiltechnics, we can undertake a range of site-based testing.

Contact our team at +44(0) 1604 781877 or enquiries@soiltechnics.net today to find out how we can help and learn more about the services we provide.

Following the publication of the AGS Guide to the Selection of Pressuremeter Testing, Soiltechnics is proud to have provided guidance on the utilisation of various pressuremeter techniques as part of our site investigations around the UK.

Collaborating For Design Efficiency: Soiltechnics and Cambridge Insitu

Soiltechnics has worked closely with Cambridge Insitu over many years bringing design efficiency to many complex foundation challenges.

Working collaboratively with Cambridge Insitu to enable cost-effective testing campaigns, allows Soiltechnics to provide expert advice regarding the specification, correct deployment and interpretation of the pressuremeter test results.

Together, we bring confidence to enable the use of cleaner and more sustainable design solutions.

The Importance of Experienced Investigation Teams

As discussed in the AGS guide, it is important that the investigation team are experienced in the deployment and operation of the various pressuremeters used by Cambridge Insitu.

This is why talking to Soiltechnics at an early stage will help the project design team achieve the best results from the tests.

How We Can Help

If you would like to tap into the extensive experience Soiltechnics can offer and discuss the use of pressuremeters on any project, along with the benefits it may bring, Angus Wilson or Stephen Cragg would love to hear from you.

Contact us at +44(0) 1604 781877 or enquiries@soiltechnics.net to find out more.