Contact Us

Materials Testing

Materials testing on samples extracted from existing structures provides a vital role in the investigation of the building. The results allow our team to accurately assess the performance and life expectancy of existing structures.

Concrete Core Compressive Strength

We commonly extract concrete core samples from floor slabs, beams and columns to determine the compressive strength. We carry these out in line with BS EN 12504-1, 12390-3 and 12390-7.

Cement Content

Cement content forms part of our materials testing services and is an important aspect of the durability and strength of a structure. If the cement content is too small it can lead to inadequate structural capability or insufficient protection to the reinforcement. Conversely, too high a cement content may lead to excessive shrinkage and thermal cracking, causing the concrete to spall.

The test involves first crushing a sample of concrete into a fine powder. We then test the powder for insoluble residue, soluble silica and lime cement. These levels are compared to control samples of the cement or from assumptions made about the source of the concrete.

Carbonation Testing (using phenolphthalein indicator)

Carbonation of concrete is caused by carbon dioxide in the atmosphere reducing the pH level. Typically concrete has a pH level of 13 which provides a passive coating to the reinforcement. At levels below 11, the passivity begins to decrease leading to corrosion of the reinforcement. We typically conduct this test in the field on a freshly exposed surface of concrete. The indicator will be pink in colour at pH greater than 9 and colourless in areas of pH less than 9. This relatively quick in-situ test provides a clear indication of the carbonated zone and the likely performance of the building. We carry out this test in accordance with BS EN 14630.

Chloride and Sulphate Content Testing

Chloride attack on concrete can cause high levels of corrosion of the reinforcement within the concrete. Accordingly, it is important to test for the presence of chloride in the concrete.

Sulphate attack has a detrimental effect on the concrete leading to reduced durability and strength. Therefore, it is important to test for the presence of sulphates within the concrete and soil below.

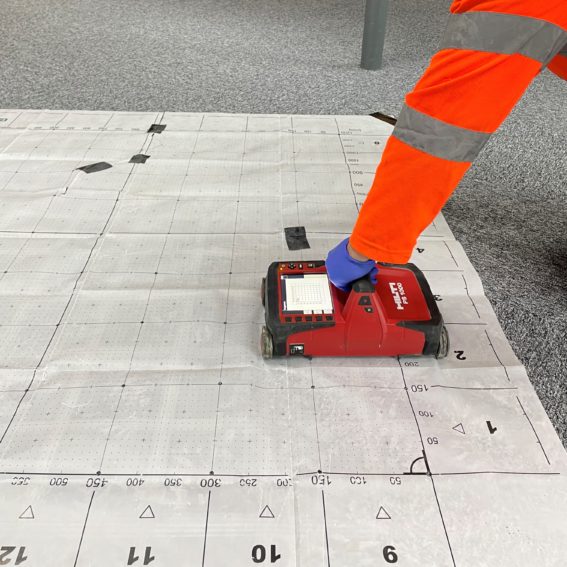

Schmidt Hammer (non-destructive)

Schmidt hammer testing is the most widely used instrument for non-destructive estimation of concrete strength. We provide an estimation of concrete strength based on empirical correlations. However, we believe the rebound hammer should be considered as a means of estimating the variation of strength within a structure, accordingly, it should be ‘calibrated’ with laboratory strength tests.

What Our Clients Say

"Vision Survey have worked with Soiltechnics for several years, initially forging a strong working relationship with their Manchester office, which has since expanded to include our respective southern offices. We appreciate their excellent professional conduct, their collaborative working approach and ultimately, in knowing that we can rely on them to meet our requirements."

Nathan Pickering, Regional Operations Lead – Vision Survey

"Soiltechnics have provided a range of soil reports, ground investigation surveys, remediation strategies and verification reports for parks and open space improvement projects in Southwark. They have also provided clear and concise expert advise on ground/soil related issues which have occurred during construction phase. Soiltechnics are a valued, reliable consultant we will continue to approach for similar schemes.”

Matthew Hill, Project Manager – Southwark Council

“With years of experience working alongside Soiltechnics on various projects, including site investigations, remediation strategy development, MMP development, and on-site supervision, I've consistently found their team to be professional, responsive, and committed to achieving project goals while upholding high environmental standards. I highly recommend Soiltechnics for any geotechnical or environmental needs.”

John Dillnut – Untye Group