Contact Us

Non-Intrusive Surveys

Non-intrusive surveys are an effective and agile way of surveying sensitive buildings where noise, damage and dust are not feasible. They also provide extensive and cost effective coverage to confirm the findings of intrusive investigations.

We are able to use a variety of methods in order to investigate structures and structural defects within a vast array of buildings. Including spalling/cracking, rust/corrosion, and RAAC investigations (Reinforced autoclaved aerated concrete), our tools and services allow us to deliver a detailed report for our clients.

Concrete Scanning

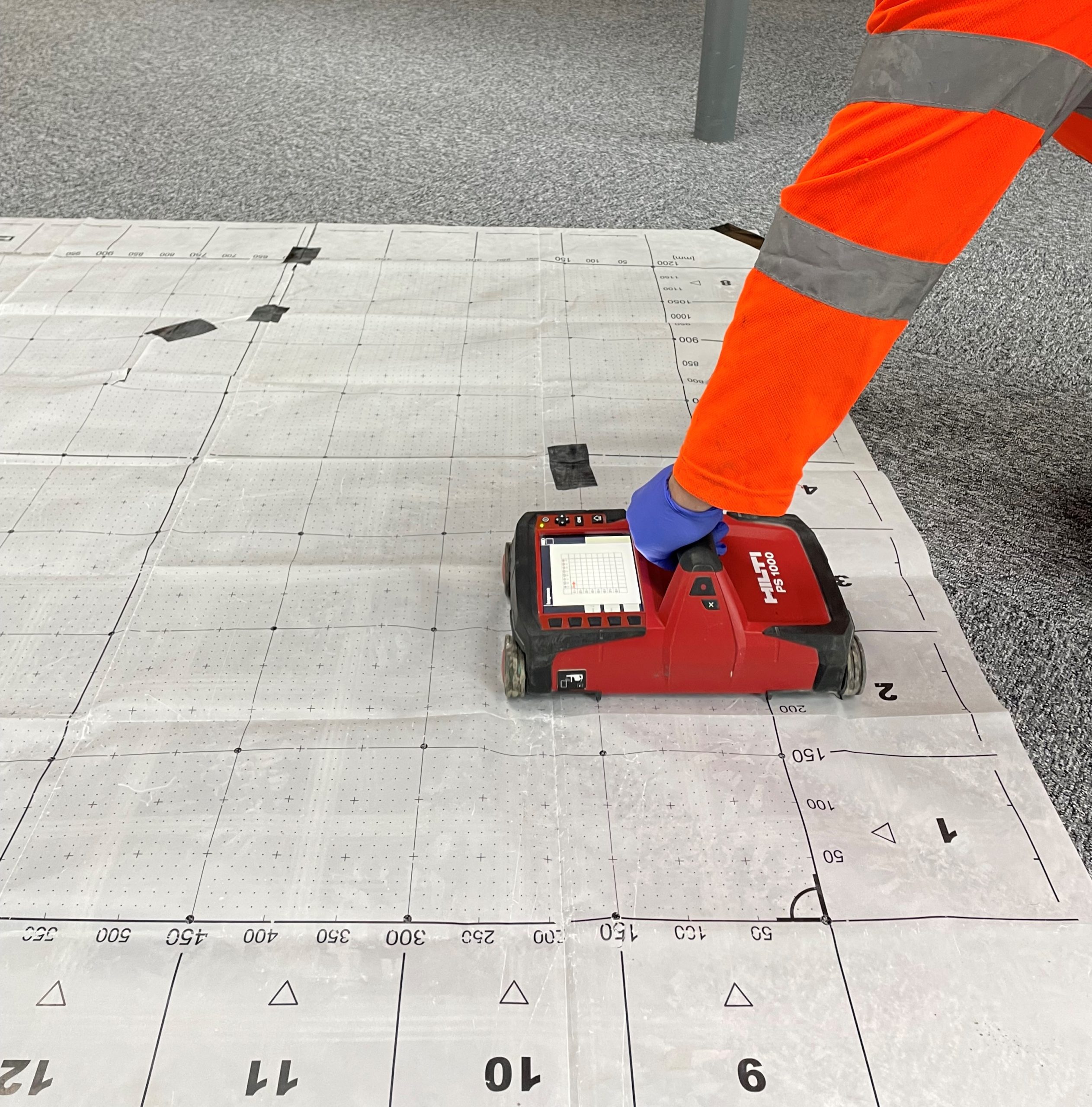

We use our PS 1000 X-SCAN concrete scanner to provide structural analysis and locate embedded objects in multiple layers. The device is capable of scanning to a detection depth of 300mm and has a localisation accuracy of ±10mm.

This provides a real-time view inside concrete structures and generates accurate images automatically for a direct on-site evaluation. We use this for locating rebars, tendons, metal and plastic conduits, glass-fibre cables, voids and timber in dry concrete structures, as well as detecting voids and cavities.

Inspection examples include floor slabs, walls, beams, columns, balconies, etc. in structures such as buildings, tunnels and bridges.

3d Laser Scanning

A 3D laser scanner is another non-intrusive tool which can scan, process and track progress on the go. It is handheld, lightweight and easy to use. We can rapidly build highly accurate 3D models within minutes, see the areas covered and route taken on site.

We use point cloud processing software to process data quickly. This gives us the ability export it to many universal formats such as LAZ, LAS, PLY and DWG. Additionally, we can produce 2D building floor plans and 3D sections through beams, columns and other structural members.

For more information about 3D laser scanning, see our Point Cloud Surveying service page.

Ultrasonic Thickness Measurement (UTM)

We use our material thickness gauge to quickly and accurately inspect the metal thickness of a wide range of structures and components that includes piping and structural steel.

We clean and lightly sand the surface of the structural member to create a flat surface for a reading to be taken. Subsequently, we place an ultrasonic couplant gel on the surface of the structural member alongside a detection probe. This provides the thickness of the structural member by measuring how long it takes for a sound pulse to travel through the material and reflect back.

Thickness measuring is essential to monitor corrosion, erosion and damage. This ensures the continued safety and operation of the inspected structural member and can help determine if any repair work/replacements are required. The method provides the required information to determine if the structural member has the appropriate thickness for which it was designed.

What Our Clients Say

"Soiltechnics have provided a range of soil reports, ground investigation surveys, remediation strategies and verification reports for parks and open space improvement projects in Southwark. They have also provided clear and concise expert advise on ground/soil related issues which have occurred during construction phase. Soiltechnics are a valued, reliable consultant we will continue to approach for similar schemes."

Matthew Hill, Project Manager – Southwark Council

"Vision Survey have worked with Soiltechnics for several years, initially forging a strong working relationship with their Manchester office, which has since expanded to include our respective southern offices. We appreciate their excellent professional conduct, their collaborative working approach and ultimately, in knowing that we can rely on them to meet our requirements.”

Nathan Pickering, Regional Operations Lead – Vision Survey

“Having worked with Soiltechnics for almost ten years, they are considered a trusted member of our supply chain. Soiltechnics completed a robust selection process which highlighted their ability to perform with the utmost professionalism in regards to customer service, value for money and site safety. It is trusted consultants like Soiltechnics who we can depend on in our pursuit to provide the perfect product for our customers.”

Gavin Williams, Senior Pre Construction Surveyor – Willmott Dixon Construction Ltd